Nylon Material for METHOD 3D Printer: The Durable and Heat-Resistant Solution

3D printing has come a long way in the last few years, with new materials and technologies making it possible to create complex and intricate designs quickly and easily. One of the most durable and heat-resistant materials used in 3D printing is nylon. Nylon material for METHOD 3D Printer, in particular, has gained popularity due to its high-quality and abrasion-resistance.

Nylon is a popular material for manufacturers due to its high durability and ability to withstand high temperatures. Its heat-resistance, combined with its durability, makes it an ideal material for replacement parts. Nylon material for METHOD 3D Printer is no exception. The material is perfect for making strong, sturdy replacement parts for machines or tools that need to be able to withstand high temperatures and heavy use.

Nylon material for METHOD 3D Printer is an excellent alternative to traditional materials that may not be as durable or heat-resistant. For example, many manufacturers use metals like aluminum or steel to create replacement parts for machines. However, these materials can be expensive and time-consuming to manufacture. Additionally, metals may not be able to withstand the same high temperatures as nylon, making them less durable in certain environments.

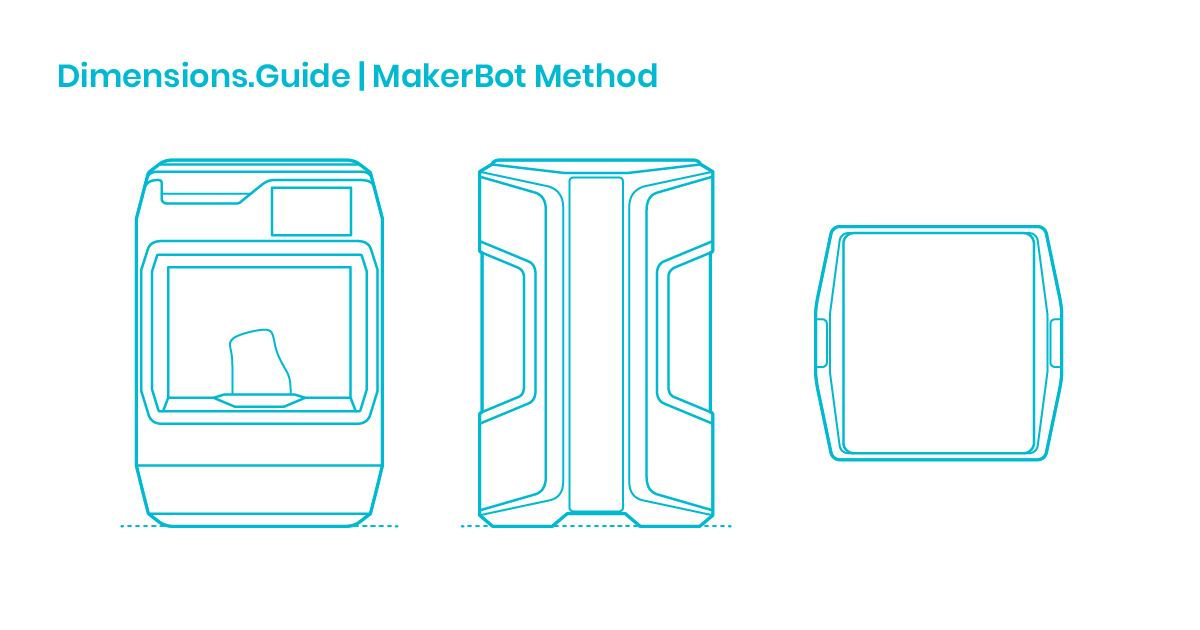

One of the great benefits of using nylon for 3D printing is its ease of use. Nylon can be used with a range of 3D printers, including MakerBot Nylon, which is specifically designed for use with METHOD 3D Printers. MakerBot Nylon is a high-strength, heat-resistant material that is ideal for creating replacement parts.

The abrasion resistance of MakerBot Nylon is also a key factor in its popularity. Abrasion is the process by which materials wear down due to constant friction or rubbing. Nylon is particularly abrasion-resistant, meaning it can withstand constant wear and tear without deteriorating. This makes it a great material for manufacturing parts that are expected to last for a long time.

Another advantage of using nylon for 3D printing is its flexibility. Nylon can be printed in a range of different densities and thicknesses to create unyielding or flexible parts that serve the intended purpose. 3D printing with nylon can also produce parts that are lightweight without sacrificing strength and durability.

When it comes to 3D printing with nylon, there are some important factors to consider. First, nylon is more difficult to print than some other materials. Its flexible nature and high melting point can make it tricky to print at times, particularly when it comes to creating intricate designs or fine details. However, with a little practice and a good understanding of the material, it is possible to create high-quality prints with nylon.

Another factor to consider when using nylon for 3D printing is the need for a heated build plate. Nylon requires a heated build plate to prevent warping and ensure proper adhesion to the printing surface. Additionally, it is recommended that nylon be printed in a well-ventilated area to reduce the risk of fumes.

Overall, Nylon material for METHOD 3D Printer is an exceptional material for creating replacement parts. Its heat-resistant properties, durability, and abrasion resistance make it a versatile material that can be used in a range of applications. 3D printing with nylon is not without its challenges, but by following best practices and taking necessary precautions, it is possible to create high-quality prints that meet the desired specifications.